How to Choose Durable Engine Spare Parts for Heavy Machinery

October 22, 2025

Transmission Upgrades That Boost Excavator Productivity

October 31, 2025Expert Tips for Preventing Hydraulic System Leaks

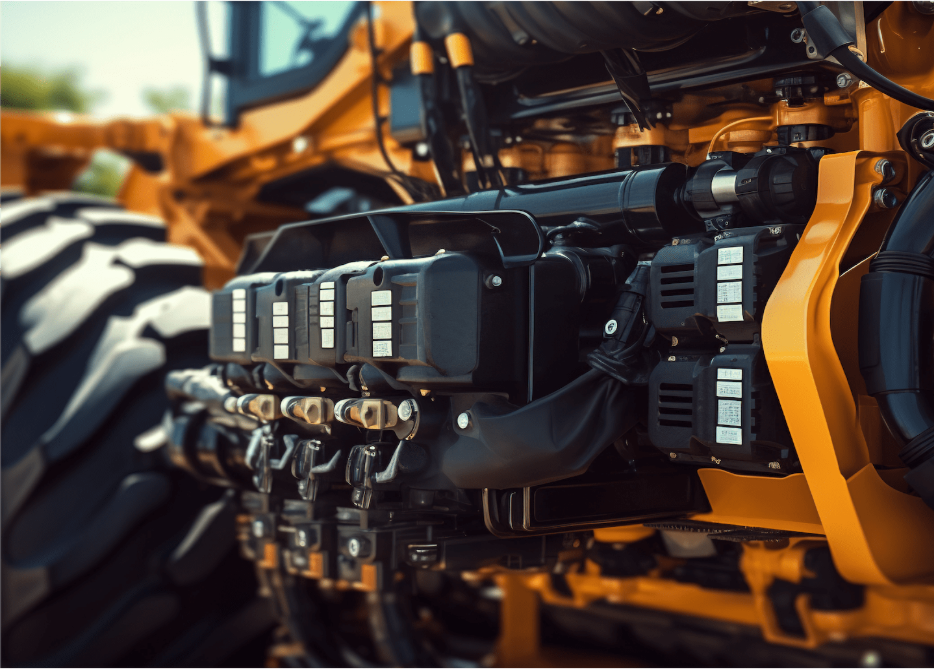

Hydraulic systems are the backbone of modern industrial machinery, powering everything from construction equipment and agricultural machinery to advanced manufacturing lines. Their ability to transmit power efficiently makes them indispensable. However, hydraulic systems are vulnerable to leaks—an issue that can silently erode productivity, increase operational costs, and compromise safety.

Even minor hydraulic leaks can result in significant fluid loss over time, leading to additional costs for replenishment and potential environmental hazards. For example, a medium-sized factory may lose thousands of liters of hydraulic fluid annually if leaks are ignored, which translates directly into tens of thousands of dollars in replacement costs and lost production hours.

Preventing leaks is not just about avoiding financial loss—it’s about maintaining system efficiency, prolonging the life of equipment, and ensuring workplace safety. By following industry best practices and adhering to standards such as ISO 4413 for hydraulic systems, maintenance teams can significantly reduce leak risks. This article provides a comprehensive guide to understanding, preventing, and managing hydraulic leaks using proven techniques, quality components, and proactive strategies.

Common Causes of Hydraulic System Leaks

Identifying why leaks occur is crucial for preventing them from happening. Hydraulic systems consist of numerous components, including seals, hoses, fittings, and pumps. Any weakness in these areas can compromise the system.

Worn or Damaged Hydraulic Seals

Hydraulic seals are the first line of defense against leaks. They maintain the integrity of pressurized fluid and prevent contamination. Over time, however, seals can degrade due to:

- High operating temperatures: Excessive heat accelerates seal wear and can cause cracking or hardening.

- Pressure fluctuations: Continuous pressure spikes can deform seals, causing gaps.

- Incompatible fluids: Using fluids that are chemically incompatible with seal materials can weaken them.

Real-world example: A steel manufacturing facility found that their hydraulic presses were leaking at the cylinder connections. After inspection, it was discovered that the seals had become brittle due to prolonged exposure to heat and an incompatible fluid blend. Replacing the seals with heat-resistant, compatible alternatives solved the issue and improved system efficiency.

Tip: Implement a seal replacement schedule based on operating hours and environmental conditions, rather than waiting for leaks to appear.

Poor Fluid Management Practices

Hydraulic fluids are the lifeblood of the system. Their cleanliness, viscosity, and compatibility play a critical role in preventing leaks. Poor fluid management can include:

- Using fluids with the wrong viscosity can stress seals.

- Delaying fluid changes beyond recommended intervals, leading to contamination buildup.

- Allowing air or moisture to enter the system reduces hydraulic efficiency.

Statistics: Studies show that up to 25% of hydraulic system failures are due to contaminated or improperly managed fluid.

Proactive step: Use filtration systems and monitor fluid conditions through routine testing. Maintain clean storage and avoid mixing fluids unless verified compatible. This ensures that both seals and moving components remain protected.

Stress on Hoses and Fittings

Hydraulic hoses and fittings are subjected to high pressure, high mechanical stress, and mechanical stress. Even minor installation errors can cause leaks over time. Common issues include:

- Improper routing: Hoses bent beyond their minimum bend radius can develop micro-cracks.

- Chafing: Hoses rubbing against machinery or other hoses degrade faster.

- Over-torqued fittings: Excessive torque can deform fittings, creating leak points.

Case study: A construction company experienced frequent leaks in excavator hydraulic lines. Upon inspection, it was found that hoses were rubbing against pivot points and sharp edges. Installing protective sleeves and re-routing hoses eliminated the leaks and extended hose life by over 50%.

Tip: Use clamps and protective covers to minimize stress on hoses and regularly inspect fittings for signs of wear.

Preventive Maintenance Tips

Preventive maintenance is the most effective way to avoid hydraulic leaks. It allows issues to be detected and addressed before they escalate.

Regular Inspection Schedules

Routine inspections are essential for detecting potential leaks early. Maintenance teams should check:

- Seals for cracks or hardening.

- Hoses for abrasion, bulging, or discoloration.

- Fittings for signs of fluid seepage.

Recommendation: Use a checklist tailored to your specific equipment, and conduct inspections at intervals defined by operating hours or manufacturer guidelines. Keeping digital logs can help identify trends and predict component failure.

Example: A logistics company implemented a weekly inspection protocol for their forklifts and found minor leaks before they caused operational downtime. Over a year, this proactive approach reduced hydraulic fluid waste by 30%.

Proper Seal and Hose Installation Techniques

Even the highest quality parts can fail if installed incorrectly. Proper techniques include:

- Lubricating seals to prevent twisting during installation.

- Ensuring hoses are routed without sharp bends or interference points.

- Using torque specifications from manufacturers for fittings.

Training benefit: Companies that provide installation training for their maintenance staff see fewer post-maintenance leaks and longer component lifespans. For instance, a manufacturing plant trained staff on correct seal installation, resulting in a 40% reduction in hydraulic leaks within six months. For high-quality seals, hoses, and fittings that support proper installation, you can view this products page.

Fluid Selection and Management Best Practices

The right fluid protects components and maintains system efficiency. Best practices include:

- Selecting fluids recommended for your equipment type and operating temperature.

- Replacing fluids at intervals aligned with manufacturer guidance.

- Monitoring fluid cleanliness using particle counters or sight glass inspections.

Pro tip: Maintain a separate, sealed storage for new and used fluids to prevent cross-contamination.

Spare Parts Selection and Sourcing

Even with meticulous maintenance, using poor-quality components can compromise your hydraulic system. Sourcing parts from reliable suppliers ensures durability and reduces system failures. For high-quality hydraulic components, you can explore trusted suppliers like Superparts, which offer a wide range of seals, hoses, and fittings that meet industry standards.

Guidance on Selecting OEM vs Aftermarket Parts

OEM parts guarantee compatibility and performance since they are designed specifically for the equipment. After-sale alternatives can be cost-effective but vary in quality. Key considerations when choosing aftermarket parts include:

- Material composition and durability.

- Supplier reputation and certification.

- Warranty and performance guarantees.

Example: A heavy machinery operator switched from low-cost aftermarket seals to certified OEM replacements. Within a year, they reported a 50% drop in leaks and reduced overall maintenance costs.

Importance of Verified Suppliers

Counterfeit or substandard parts are a major cause of hydraulic system failures. To avoid them:

- Source from authorized distributors.

- Verify supplier credentials and customer reviews.

- Ensure components meet international standards such as ISO 8434 for fittings and SAE J516 for hoses.

Verified suppliers reduce risk, increase system reliability, and provide peace of mind during maintenance cycles.

Minimizing Downtime and Costs

Hydraulic leaks can halt operations and escalate costs quickly. Preventive strategies include:

- Scheduled Maintenance: Plan maintenance during low-production periods to minimize operational interruptions.

- Redundancy: Maintain an inventory of critical components to quickly replace worn or leaking parts.

- Cost Analysis: Compare the long-term cost of frequent repairs versus investing in premium parts and preventive measures.

Case Study: A logistics company analyzed downtime costs versus investment in premium hydraulic seals and hoses. They found that while premium components were more expensive upfront, the reduced downtime and fluid losses resulted in net savings within six months.

Leak Detection Techniques

Early detection is critical to prevent minor leaks from escalating into system failures.

- Visual Inspection: Check for drips, residue, or wet spots around seals and connections.

- Pressure Tests: Sudden pressure drops can indicate a leak even if it is not visible.

- Sensor Monitoring: Advanced systems use sensors to detect fluid level changes, temperature spikes, or pressure anomalies, triggering real-time alerts.

Tip: Combining traditional visual inspections with technology-driven monitoring ensures comprehensive leak detection and faster response times.

Environmental and Safety Considerations

Hydraulic leaks not only affect productivity but also pose environmental and safety risks. Leaking fluid can:

- Create slippery surfaces, increasing the risk of workplace injuries.

- Contaminate soil or waterways if not contained.

- Violate environmental regulations, potentially leading to fines.

Proactive measures: Use drip pans, absorbent mats, and spill kits near hydraulic equipment. Regularly train staff in spill containment and reporting procedures. These measures minimize environmental impact and maintain compliance with safety standards.

Conclusion

Preventing hydraulic system leaks is a multifaceted effort requiring knowledge, discipline, and quality components. By understanding common causes—worn seals, poor fluid management, and stressed hoses—and implementing preventive maintenance practices, organizations can extend the life of their equipment, reduce costs, and maintain operational efficiency. For inquiries about sourcing parts or expert guidance on hydraulic system maintenance, you can reach out directly through this contact page.

Frequently Asked Questions About Preventing Hydraulic System Leaks

1. What are the main causes of hydraulic system leaks?

Hydraulic leaks are commonly caused by worn or damaged seals, improper fluid management, and stress on hoses and fittings. Regular inspections can help identify these issues early.

2. How can regular maintenance prevent hydraulic leaks?

Routine inspections, proper seal and hose installation, fluid management, and monitoring system pressure and temperature help prevent leaks and prolong component life.

3. Should I use OEM or aftermarket parts to prevent leaks?

OEM parts ensure compatibility and reliability, while high-quality aftermarket parts can be cost-effective. Always source from verified suppliers to avoid substandard components.

4. What leak detection techniques are most effective?

Visual inspections, pressure tests, and sensor-based monitoring systems are effective. Combining manual and technology-driven methods ensures early leak detection.

5. How do hydraulic leaks impact costs and productivity?

Leaks can lead to fluid loss, equipment downtime, and higher maintenance costs. Preventive measures and proper sourcing of parts minimize interruptions and save money in the long term.