Transmission Upgrades That Boost Excavator Productivity

October 31, 2025

Why Quality Control in Heavy Equipment Spare Parts Manufacturing Matters

November 24, 2025Choosing the Right Ground Engaging Tools for Maximum Efficiency

Choosing the best ground engaging tools heavy machinery can have a significant impact on project efficiency and equipment longevity. Selecting high-quality GETs not only enhances the performance of your machinery but also reduces operational costs, minimizes downtime, and increases the lifespan of your equipment. In this article, we will explore the best ground engaging tools heavy machinery options, helping construction site managers, heavy machinery operators, and procurement specialists make informed decisions. Ground engaging tools, commonly referred to as GETs, are the components of heavy machinery that come into direct contact with the ground.

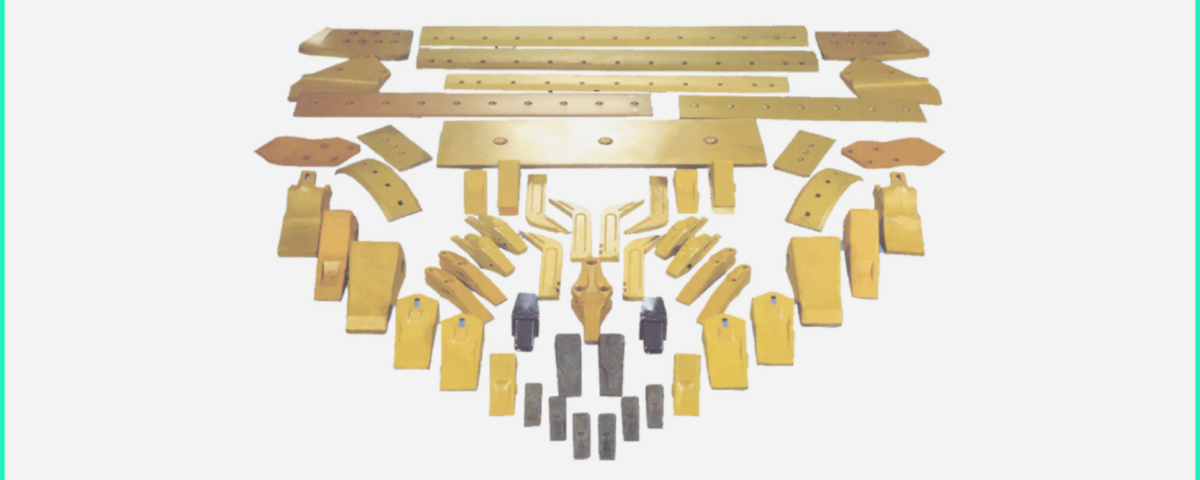

These include bucket teeth, adapters, and cutting edges. GETs play a crucial role in excavation, material handling, and overall machine performance. Choosing the right tools ensures maximum efficiency and durability while optimizing fuel consumption. This guide will provide insights into understanding GETs, key selection factors, bucket tooth types, supplier considerations, durability testing, and maintenance of best practices. For high-quality GET solutions, explore Super Parts for a wide range of options.

Understanding Ground Engaging Tools

What Are Ground Engaging Tools?

Ground engaging tools (GETs) are essential attachments on heavy machinery, including bucket teeth, adapters, cutting edges, and wear plates. These components directly impact how effectively a machine interacts with soil, rock, and other materials.

Role of GETs in Machinery Performance

GETs influence the digging capacity, loading efficiency, and overall operational productivity of construction equipment. High-quality GETs reduce strain on the machine, lower fuel consumption, and minimize wear on core components. On the other hand, poorly chosen GETs can result in frequent replacements, increased operational costs, and reduced machine lifespan.

Importance of GET Selection

Choosing the appropriate GETs directly affects operational efficiency. Proper selection ensures optimal penetration into soil or rock, reduces machine wear, and improves fuel efficiency. It also affects downtime and project timelines, making it essential for site managers to prioritize GET selection in procurement decisions.

Key Factors When Choosing GETs

Wear Resistance

Wear resistance is a critical factor when selecting GETs. The materials and design of GETs must withstand abrasive conditions, heavy loads, and prolonged usage. Wear-resistant tools last longer, reducing replacement frequency and overall maintenance costs.

Common Wear Testing Methods

Laboratory wear tests, such as the pin-on-disk method or abrasion testing, provide insights into the durability of different GET materials. Field testing under real operating conditions also helps assess performance and wear patterns.

Steel Grades

Different steel grades are used in manufacturing GETs, each offering unique properties:

- High Manganese Steel: Excellent impact resistance, suitable for heavy-duty applications, but can wear faster in abrasive soils.

- High Chromium Steel: Exceptional wear resistance, ideal for abrasive environments, but higher cost.

- Carbon Steel: Cost-effective and moderately durable, suitable for lighter workloads.

Choosing the right steel grade balances durability, cost, and suitability for specific soil or rock conditions.

Replacement Cycles

Tracking replacement cycles is essential for optimizing machinery uptime. Long-lasting GETs reduce the frequency of replacements, saving time and labor costs. Well-maintained GETs ensure machines operate efficiently, avoiding unexpected downtime.

Compatibility with Machinery

GETs must be compatible with specific machine models and workloads. Using mismatched components can lead to premature wear, decreased efficiency, and potential equipment damage. Always verify manufacturer specifications before selecting GETs. Learn more about contacting suppliers for compatibility inquiries at Superparts Contact.

Comparing Bucket Tooth Types

Bucket teeth are available in various designs, each suited for different applications:

Standard Teeth

- Pros: Versatile, suitable for general excavation and material handling.

- Cons: May wear faster in highly abrasive conditions.

Heavy-Duty Teeth

- Pros: Enhanced durability for rocky or dense materials.

- Cons: Higher cost and may reduce penetration efficiency in soft soil.

Pointed Teeth

- Pros: Excellent penetration for hard soil and rock.

- Cons: Less effective in soft, loose materials.

Flat Teeth

- Pros: Ideal for grading and smoothing surfaces.

- Cons: Limited digging capacity in hard or rocky terrain.

Visual diagrams comparing these types help operators understand suitability for different ground conditions. Check the detailed list of GET products at Superparts Products.

Supplier Selection and Comparison

Choosing a reliable GET supplier is as important as selecting the right tools. Key factors to consider include:

- Quality: Ensure components meet industry standards and are tested for durability.

- Availability: Timely delivery of parts to avoid operational delays.

- Warranty: Provides assurance of product reliability.

- Cost: Balance between affordability and long-term durability.

Durability Testing Methods

Laboratory Testing

Laboratory tests evaluate wear resistance, impact strength, and material hardness. Common tests include abrasion resistance tests and impact testing under controlled conditions. For high-quality engine parts, choosing components tested for durability ensures better performance and longevity, reducing overall maintenance costs.

Field Testing

Field tests simulate actual operating conditions, assessing how GETs perform under different soil types, load conditions, and working hours. Monitoring wear patterns helps in predicting replacement schedules.

Real-World Case Studies

Using tested and validated GETs in construction projects has shown measurable improvements in efficiency. Reduced downtime, lower fuel consumption, and extended tool lifespan highlight the value of durability testing before procurement.

Best Practices for Maintenance

Regular Inspections

Routine inspection of GETs helps identify wear and damage early. Operators should check for cracks, loose components, and uneven wear.

Early Detection of Wear and Damage

Identifying wear patterns early allows for timely replacements, preventing machine damage and ensuring safety.

Maintenance Strategies

- Rotate bucket teeth regularly to ensure even wear.

- Use wear indicators to monitor component health.

- Maintain records of replacement cycles to optimize procurement and maintenance planning.

Implementing these strategies can significantly extend GET lifespan and maintain heavy machinery efficiency.

Conclusion

Selecting the best ground engaging tools heavy machinery is crucial for maximizing operational efficiency, reducing downtime, and extending equipment lifespan. By understanding the types of GETs, evaluating wear resistance, choosing the right steel grades, monitoring replacement cycles, and selecting reliable suppliers, construction site managers and operators can make informed decisions that enhance productivity and reduce costs.

Regular durability testing and preventive maintenance further ensure that GETs perform optimally under various operating conditions. Following these guidelines will lead to improved project timelines, lower operational costs, and increased equipment reliability.

Frequently Asked Questions (FAQs)

1. What are Ground Engaging Tools (GETs) and why are they important for heavy machinery?

GETs are parts like bucket teeth, adapters, and cutting edges that interact with the ground. They are essential for efficient machine performance, reducing wear, fuel consumption, and downtime.

2. How can wear resistance affect the performance of Ground Engaging Tools?

High wear resistance helps GETs last longer, reduces frequent replacements, and minimizes maintenance costs by preventing premature wear in harsh conditions.

3. What is the importance of regular maintenance for Ground Engaging Tools?

Regular inspections detect early wear, allowing for timely replacements and preventing machine damage. Maintenance strategies like rotating teeth and tracking cycles extend GET lifespan and reduce downtime.

4. How does GET selection impact fuel consumption?

Choosing the right GETs improves digging efficiency, which reduces the strain on the machine, leading to lower fuel consumption and better overall cost efficiency.

5. How can I ensure GETs are compatible with my machinery?

Always check the machine manufacturer’s specifications for GET compatibility. Using mismatched parts can cause premature wear and reduce machine efficiency.