How Reliable Spare Part Delivery Minimizes Machinery Downtime

November 24, 2025

A Heavy Machinery spare parts buying checklist

December 15, 2025Best Undercarriage Maintenance Tips and Practices to Extend Equipment Life

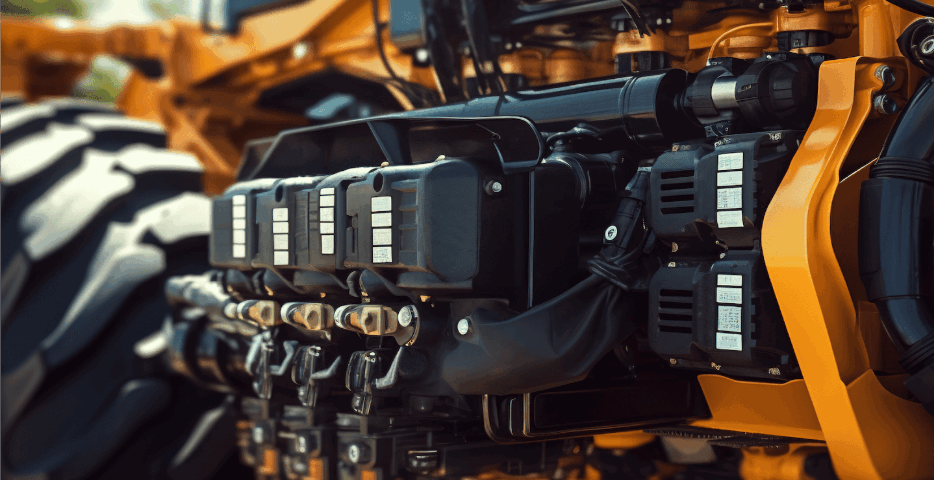

The undercarriage of heavy equipment is exposed to some of the harshest working conditions on job sites. From abrasive materials to uneven terrain and high-impact operations, this section of the machine absorbs the majority of ground contact and movement. Because of this, undercarriage components-such as track chains, rollers, idlers, sprockets, and shoes-face consistent wear throughout an equipment’s lifecycle.

For maintenance supervisors, ensuring that the undercarriage stays in optimal condition is essential. A neglected undercarriage leads to higher fuel consumption, faster component deterioration, costly breakdowns, and reduced performance. On the other hand, proactive maintenance and timely replacement significantly extend equipment life, reduce operating costs, and ensure maximum uptime.

At Super Parts, we understand how important dependable equipment is for demanding industries. At Super Parts, we are more than just a spare parts supplier; we are a trusted partner for businesses in the construction, mining, and road equipment industries. Based in Sharjah, UAE, we specialize in delivering high-quality aftermarket spare parts for Caterpillar and Komatsu machinery, helping companies keep their heavy equipment running at peak performance. With proper undercarriage care and access to premium aftermarket components, you can minimize unexpected failures and improve fleet reliability.

Below is a comprehensive guide on the best undercarriage maintenance practices, built specifically for supervisors who want long-term machine efficiency and reduced total cost of ownership.

Why Undercarriage Care Is Critical for Equipment Performance

The undercarriage can account for up to 50% of total maintenance costs associated with tracked machinery. Therefore, maintaining it properly is vital not just for machine health but also for cost management.

Undercarriage Wear Directly Impacts Productivity

When undercarriage components wear unevenly or prematurely, the machine loses traction, efficiency, and stability. This affects digging power, speed, maneuverability, and fuel consumption. Poor performance inevitably leads to downtime, lost productivity, and increased repair budgets.

Preventive Maintenance = Uptime Optimization

Breakdowns do not happen suddenly; they begin with undetected early wear. By implementing preventive measures such as regular inspections, cleaning routines, track tension checks, and wear monitoring, supervisors can identify issues before they escalate. This approach ensures uptime optimization, allowing repairs to be scheduled strategically, reducing emergency stoppages and costly disruptions.

Key Undercarriage Maintenance Tips for Supervisors

Proper maintenance requires a combination of daily habits and scheduled inspection routines. Here are the essential undercarriage maintenance tips that every supervisor should enforce:

1. Conduct Regular Visual and Technical Inspections

Daily or shift-based inspections are one of the most effective ways to detect early signs of failures. Supervisors should ensure checks include:

- Track chain stretch

- Worn sprocket teeth

- Cracked or broken track shoes

- Oil leaks around rollers

- Damaged idlers

- Loose or missing bolts

- Uneven wear patterns

Even minor issues, if ignored, can trigger serious failures down the line.

2. Clean the Undercarriage Thoroughly

A significant contributor to premature wear is debris buildup. Materials such as sand, wet clay, rocks, and gravel accumulate in tight areas, creating excessive friction.

A cleaning routine should be performed:

- At the end of every shift in muddy or rocky environments

- Before performing tension adjustments

- Before long-term storage

- After working in extremely abrasive soil

Proper cleaning results in smoother operation and slower wear rates.

3. Track Tension Must Be Adjusted Correctly

Track tension is one of the most important factors affecting undercarriage life. Incorrect tension causes unnecessary stress on every component.

Loose Track Issues:

- Increases derailment risks

- Causes instability

- Accelerates wear on idlers and rollers

Overly Tight Track Issues:

- Increases fuel consumption

- Generates excessive heat

- Speeds up wear on chains, links, and rollers

Supervisors must ensure tension is adjusted according to the manufacturer’s guidelines and jobsite conditions. For example, sand requires tighter tension than muddy terrain.

4. Lubricate Components as Recommended

Rollers, idlers, and links often contain sealed or lubricated components. Proper lubrication reduces friction, controls temperature, and improves longevity. Using the correct type of grease or oil based on OEM recommendations is extremely important.

Understanding Wear Monitoring and Its Importance

Wear monitoring is an essential strategy for predicting failures and scheduling replacements at the ideal time.

Measure Components to Predict Replacement Intervals

Supervisors should regularly measure wear on:

- Track links

- Bushings

- Idlers

- Sprockets

- Rollers

Using calipers, wear gauges, or ultrasonic tools ensures accurate tracking of a component’s lifespan. This helps in planning downtime effectively.

Identify Abnormal Wear Patterns

Abnormal wear often indicates:

- Alignment issues

- Operator misuse

- Faulty rollers

- Incorrect tension

- Material buildup

Solving these root causes early prevents further damage.

Track Tension: Why It’s Crucial for Equipment Life

Track tension is such a critical part of undercarriage maintenance that it deserves its own dedicated focus.

Signs of Incorrect Track Tension

Supervisors should train operators and technicians to identify tension problems early. Common signs include:

- Excessive vibration

- Uneven chain sag

- Increased fuel usage

- Strange noises during travel

- Faster wear on rollers or idlers

How to Check and Adjust Tension Properly

- Park the machine on flat ground.

- Clean the undercarriage thoroughly.

- Measure the sag as per OEM guidelines.

- Use the tensioning valve or adjuster to set proper slack.

- Recheck tension after machine operation.

Consistent monitoring saves thousands in repair costs.

Replacement Intervals: Knowing When to Change Components

Replacing undercarriage parts on time ensures operational stability.

Signs It’s Time to Replace Undercarriage Parts

- Sharp or hooked sprocket teeth

- Excessive bushing wear

- Flattened rollers

- Elongated track chains

- Broken or severely worn track shoes

- Oil leakage from rollers or idlers

Ignoring these signs puts the entire machine at risk.

Timely Replacement Prevents Secondary Damage

Delaying replacement can damage:

- Track frames

- Travel motors

- Final drives

- Hydraulic lines

- Suspension systems

Early replacement always costs less than repairing major structural damage.

Choose Reliable Spare Parts for Longer Equipment Life

The quality of spare parts greatly affects machine performance.

Why High-Quality Parts Matter

Premium undercarriage components ensure:

- Better lifespan

- Proper fit

- Smooth operation

- Enhanced durability

- Lower maintenance frequency

- Reduced risk of unexpected failures

Low-grade parts may seem cheaper initially but cost far more due to their faster wear rate.

How Super Parts Supports Your Equipment

Super Parts offers high-quality aftermarket undercarriage parts for Caterpillar and Komatsu equipment.

Our consistent availability, strong quality control, and reliable supply chain make us a trusted partner for equipment owners across the UAE and beyond.

Proactive Strategies for Maximum Uptime Optimization

To maintain peak performance, supervisors should build a proactive maintenance culture.

Create a Structured Maintenance Calendar

Plan:

- Daily inspections

- Weekly cleaning routines

- Monthly wear monitoring

- Scheduled lubrication

- Quarterly undercarriage audits

- Annual component overhauls

This ensures no area of maintenance is overlooked.

Operator Training Is Essential

Operators directly influence undercarriage wear. Training helps them:

- Avoid unnecessary spinning

- Reduce travel at high speeds

- Take smoother turns

- Avoid side-loading

- Maintain proper work angles

Well-trained operators can increase undercarriage lifespan by as much as 20-30%.

Conclusion: Protect Your Investment Through Smart Undercarriage Maintenance

The undercarriage is one of the most expensive and hardworking systems on heavy machinery. With proper care-through track tension adjustments, wear monitoring, cleaning, regular inspections, and timely replacements-maintenance supervisors can drastically reduce failures and extend the life of their equipment.

Proactive maintenance not only lowers costs but also improves productivity, safety, and uptime.

Backed by high-quality undercarriage spare parts from Super Parts, equipment owners can rely on durable, high-performing components that support long-term fleet efficiency. By investing in proper maintenance today, you safeguard your equipment’s future-keeping machines working smoothly across construction, mining, and roadwork operations. For reliable undercarriage parts and expert support, contact Super Parts today and keep your equipment performing at its best.

FAQ

1. What are the most important undercarriage maintenance tips for heavy equipment?

Regular inspections, proper track tension, debris cleaning, and wear monitoring are essential for long-lasting undercarriage performance.

2. How often should I inspect my equipment’s undercarriage?

Daily or shift-based inspections are recommended, especially in harsh or abrasive working conditions.

3. Why is correct track tension important for equipment life?

Proper tension reduces stress on rollers, chains, and idlers, preventing premature wear and costly breakdowns.

4. When should undercarriage parts be replaced?

Replace components when significant wear, chain stretch, damaged shoes, or worn sprocket teeth are detected.

5. Where can I find high-quality undercarriage spare parts for Caterpillar and Komatsu equipment?

Super Parts provides premium aftermarket undercarriage components designed to maximize performance and durability.