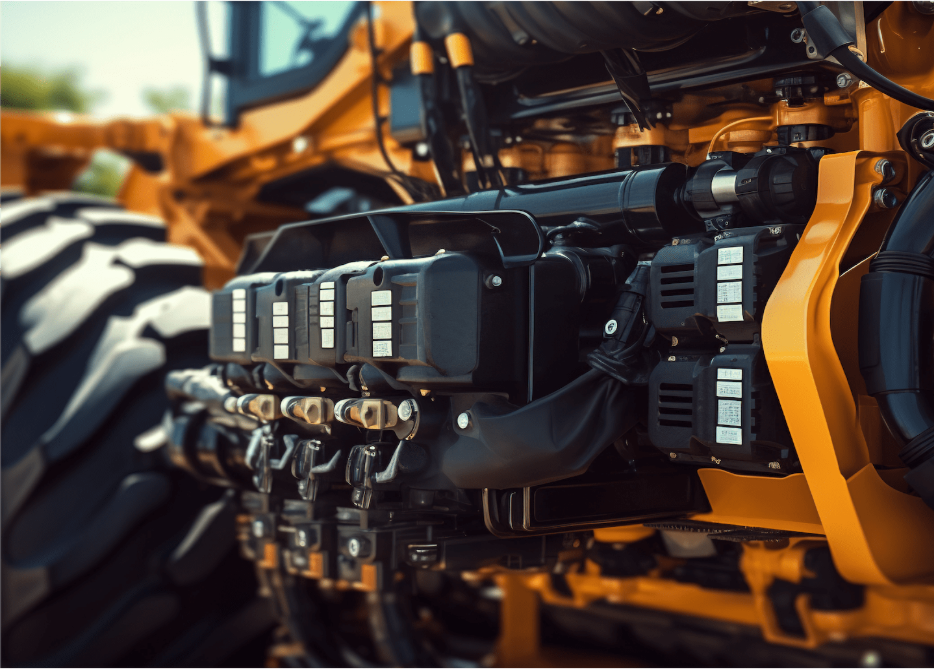

Best Undercarriage Maintenance Tips and Practices to Extend Equipment Life

December 9, 2025A Heavy Machinery spare parts buying checklist

When it comes to maintaining construction, mining, or road equipment, buying the right spare parts is not just important-it’s essential. Even a minor mismatch in part compatibility can cause operational delays, mechanical failures, and unnecessary financial losses. This is why procurement teams and heavy machinery buyers rely on a solid spare parts buying checklist to ensure accuracy, quality, and long-term reliability.

With the increasing demand for durable, high-performing machinery components, suppliers also play a crucial role in the procurement process. At Super Parts, we understand how valuable your heavy equipment is to your business. Based in Sharjah, UAE, we specialize in high-quality aftermarket spare parts for Caterpillar and Komatsu machinery. More than just a supplier, we serve as a trusted partner helping businesses minimize downtime and keep their operations running smoothly.

Below is a comprehensive checklist designed to help buyers make informed, mistake-free purchases every time.

1. Start by Clearly Defining Your Requirements

The first step in any procurement process is understanding exactly what you need. Heavy machinery comes with complex parts that differ based on model, generation, and usage conditions.

Identify the exact machinery model

Record the equipment’s model number, serial number, and production year. Even a slight variation in model versions can change the part specifications. This step minimizes the chances of ordering the wrong component.

Consider your operating environment

Machinery used in harsh conditions-such as mining or construction-often requires heavy-duty parts. Identifying how and where your machine operates helps determine whether you need standard or reinforced components.

Run compatibility checks

Compatibility issues are among the most common procurement challenges. Always cross-check part compatibility with manufacturer guidelines or consult a technical expert. At Super Parts, our team assists buyers in verifying compatibility for both Caterpillar and Komatsu equipment, ensuring every purchase is safe and reliable.

2. Conduct Thorough Part Verification

The second key stage is part verification, which ensures that what you are buying is accurate, authentic, and suitable.

Verify OEM vs aftermarket options

Quality aftermarket parts-such as those offered by Super Parts-can provide the same performance at a more cost-effective price. Understanding your requirements and budget helps you make the right choice.

Check part documentation

Access to drawings, catalogs, or specification sheets helps confirm that the part matches your machine’s needs. Missing documentation can lead to costly mix-ups.

Check certifications and quality standards

Look for suppliers that follow strict quality control standards. Certifications, durable materials, and brand authenticity all point to reliable products. At Super Parts, we maintain consistent quality checks to ensure every part delivers dependable performance.

3. Vet the Supplier Before Placing Your Order

One of the most crucial-and often overlooked-steps is supplier vetting. Choosing the right supplier can prevent issues related to delivery delays, poor quality, or after-sales problems.

Assess the supplier’s experience and reputation

Years in business, industry expertise, and customer feedback are strong indicators of reliability. Super Parts has built a reputation as a dependable aftermarket parts provider for Caterpillar and Komatsu machinery across the UAE.

Confirm stock availability and delivery timelines

Downtime is extremely costly in industries like construction and mining. Always verify inventory availability before ordering to avoid delays. A well-organized supplier ensures fast and accurate delivery.

Check transparency in pricing and warranties

A trustworthy supplier will provide clear quotations, warranty details, and no hidden fees. Transparency helps procurement teams plan budgets more efficiently.

Evaluate after-sales support

Support does not end with the purchase. Choose suppliers that provide technical guidance, warranty handling, and responsive customer service. Super Parts offers reliable post-purchase support, giving buyers full confidence in their procurement decisions.

4. Ensure Order Accuracy Before Finalizing

Accurate ordering is essential to avoid incorrect shipments, delays, and costs associated with returns.

Double-check part numbers

Even a single digit error can lead to receiving the wrong part. Always verify part numbers across documentation, supplier catalogs, and internal inventory systems.

Confirm quantity, lead time, and shipping method

Maintaining clarity on quantities and delivery timelines ensures operations remain uninterrupted. Procurement best practices recommend finalizing all details in writing before payment.

Use proper procurement documentation

Internal approvals, purchase order formats, and supplier confirmations all contribute to order accuracy. A structured procurement process ensures smooth coordination between field teams, warehouse staff, and suppliers.

5. Review Return Policies, Warranty Coverage & Support

Understanding return and warranty policies protects your business from unexpected losses.

Review return policies carefully

In case of compatibility issues or damaged products, a clear return policy helps buyers avoid unnecessary financial burdens.

Check what the warranty covers

Warranties vary among suppliers. Ensure you understand whether the warranty covers manufacturing defects, usage-related issues, or specific conditions.

Evaluate after-sales support and guidance

A good supplier will support buyers with installation guidance, part usage tips, and general troubleshooting.

6. Compare Prices Wisely-Not Just the Lowest Cost

While price matters, it should not be the only deciding factor.

Research average market rates

This prevents overpaying and helps you understand the reasonable price range for a specific spare part.

Calculate total cost of ownership

Consider factors such as:

- Durability

- Performance

- Delivery time

- Supplier reliability

- Warranty benefits

Choosing the cheapest option often leads to poor performance or repeat purchases, costing more over time. High-quality aftermarket parts, like those offered by Super Parts, balance affordability with durability.

7. Run Final Compatibility & Fitment Checks

Before completing the purchase, perform a final review.

Cross-check with manufacturer guidelines

Manufacturer manuals offer detailed explanations of required specifications. This step ensures the part fits correctly and performs safely.

Consult technical experts if needed

Complex machinery may require expert advice. Super Parts provides customers with technical support to help them make accurate decisions.

Verify fitment requirements

Some components require measurements or tools for precise installation. Confirming these details avoids installation challenges or part damage.

8. Build a Long-Term, Efficient Procurement Strategy

A one-time purchase is just the beginning. Building a structured procurement strategy improves accuracy, reduces downtime, and strengthens supplier relationships.

Maintain a list of verified suppliers

Working with a trusted supplier like Super Parts ensures consistent quality and dependable delivery every time.

Track order history and supplier performance

Monitoring order accuracy, delivery speed, and product quality helps refine future buying decisions.

Implement procurement best practices

This includes proper documentation, internal communication, and regular evaluations of purchasing processes.

Conclusion: Buy Smarter and Keep Your Machines Running Strong

Purchasing heavy machinery spare parts is a responsibility that requires precision, research, and trusted partnerships. A detailed spare parts buying checklist helps procurement teams avoid common pitfalls, reduce downtime, and ensure their machinery performs at its best.

At Super Parts, we are committed to delivering high-quality aftermarket spare parts for Caterpillar and Komatsu machinery. As a trusted partner for industries across the UAE, we support buyers in making informed, accurate, and cost-effective procurement decisions. Contact us today to your spare parts needs and get expert guidance from our team.

FAQ

1. What is a spare parts buying checklist?

A spare parts buying checklist is a step-by-step guide that helps buyers verify part accuracy, compatibility, and supplier reliability before purchasing.

2. Why is part verification important in machinery maintenance?

Part verification ensures the component matches the machine’s specifications, preventing installation issues and costly downtime.

3. How does supplier vetting reduce procurement risks?

Supplier vetting helps buyers choose trusted suppliers who offer quality parts, proper documentation, and reliable delivery.

4. What factors should be reviewed before finalizing a spare parts order?

Buyers should confirm part numbers, quantities, lead times, and documentation to ensure order accuracy.

5. Why are compatibility checks essential when buying heavy machinery parts?

Compatibility checks ensure the part fits the machine correctly, improving performance and avoiding operational disruptions.